Grease Trap and Interceptor Removal

A building company hired NLR to oversee the removal of a grease trap and interceptor reticulation system (2x 3000L tank) located in Brisbane's CBD, and to clean the area of any possible grease contamination, using pressure cleaning and HEPA air scrubbers.

#Project highlights

2x

3000 Litre tanks

Pressure

cleaning & anti microbial treatment

Novair 1000

and Phoenix HEPA Guardian R filtration units

VOC Gas Monitoring

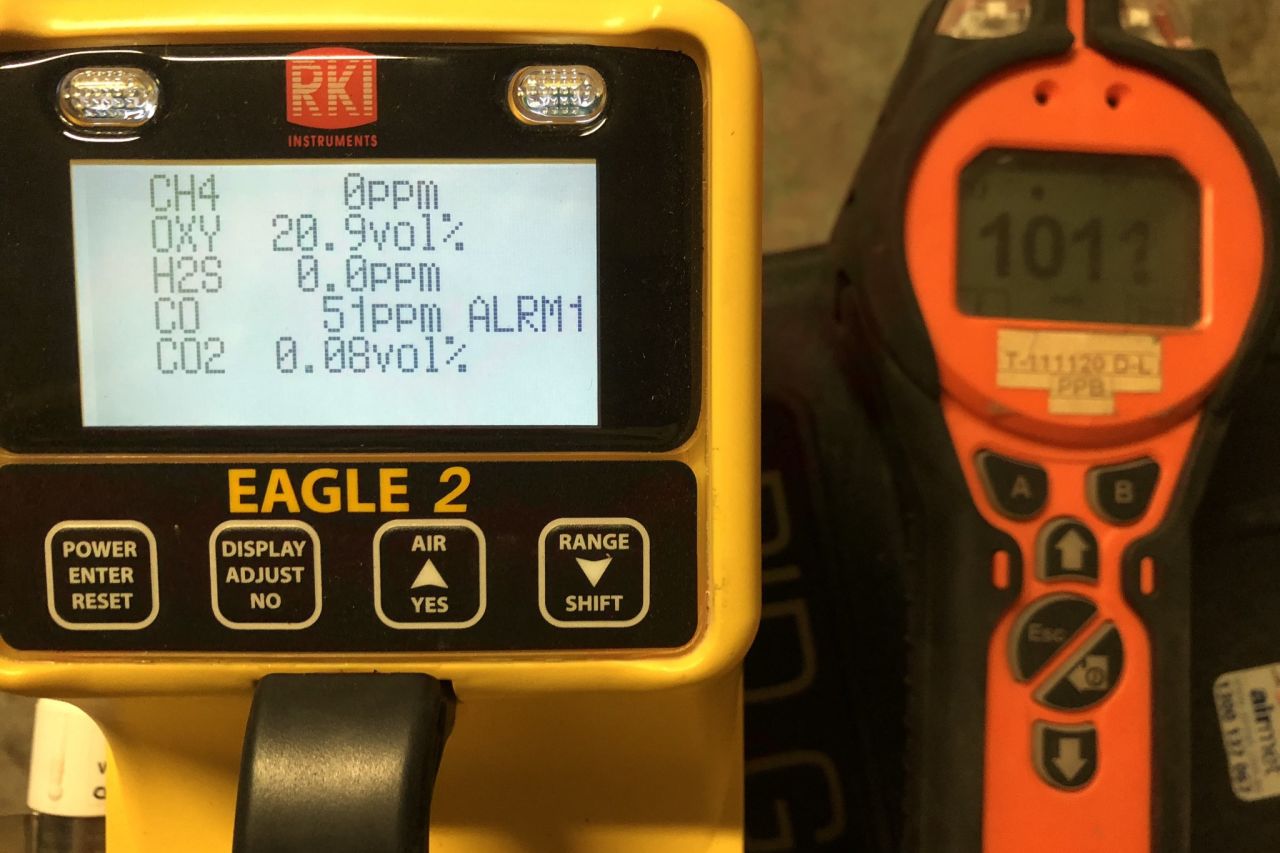

Photoionization Detector and Gas Analyser Meter

#Project Overview

NLR restorations was called to oversee the removal of a gas trap and interceptor reticulation system, to make sure that containment barriers were up to standard, and to contain and remediate any grease contamination.

First attending the site, NLR technicians installed two HEPA filtration units, to set up a negative venting system. Adjustment to the containment area was also done where appropriate.

Containment barrier set up

HEPA filtration unit set up

#Sewage Gas Removal

Afterwards, NLR helped oversee the deconstruction and removal of components of the gas trap and interceptor system. This involved decontamination cleaning rinse to the disassembled units before removal off-site. The technicians also used a pressure truck mount system to pressure clean any decontaminated areas due to spills.

Component and Contamination spill requiring Pressure clean

#Environmental assessment

Lastly, after a period of HEPA air scrubbing, to ensure the area was safe for further works, New Life Restoration used a photoionized detector and gas analyser, to determine the air quality of the area.

Air Quality reading withing acceptable limits

#Results

Air quality monitoring showed all results as being within acceptable limits. The containment barrier was taken down and the HEPA filtration units removed offsite. The area was now safe for further works to occur. If you have any grease clean up enquiries or are interested in our range of specialised cleaning, please click on the link below.